Engineers in Scrubs

Michael Cancilla, MEng’14, and team created an innovative piece of equipment that is helping Ugandan surgeons treat more patients, in less time, at little cost.

Warning: contains graphic images of surgical procedures

Transcription

Some Ugandan surgeons at Mulago Hospital in Kampala came to UBC with a problem. And the problem was, they go to work and they have all these patients to treat, but they don’t have the right materials to do it.

If you break your femur in a car accident in Vancouver and go to Vancouver General Hospital, then the surgeons are going to fix it and they’re going to use a surgical drill that costs around $30,000. So you can imagine that in Uganda, in a lower resource setting, this technology is not as appropriate, and even if you do have a high quality surgical drill, you have to sterilize it after each procedure. So you drill, and then you sterilize, and then you drill, and then you sterilize, and that’s a big bottleneck in a hospital like Mulago. The other option is to use a hand drill, which is a manual drill that works kind of like an eggbeater, you can imagine, and to drill holes with this is very labour intensive and it takes about twenty minutes per hole. And this is a really bad problem because the longer that it takes for you to get treatment, the less positive your outcome is. That’s a grudging, tough call that they have to make on a day to day basis.

So, they came to us with the solution that they knew they could use regular power drills for the surgeries they need to do, excerpt for that regular power drills can’t be sterilized like surgical drills can. If we could make a cover to allow it to stay sterile, then they would be able to use a drill from their regular hardware store to do these surgeries.

You could think of the drill cover as like a MEC dry-bag, in that you can put the drill inside of it and it features a folding clasp-buckle, the same as a dry-bag would. Except for, there’s a mechanical interface that the drill can connect to on the inside of the bag and transfer its rotation to the outside of the bag without compromising the sterile seal of the bag. No bacteria or bugs or anything can transfer from the OR to the drill, or the drill to the OR.

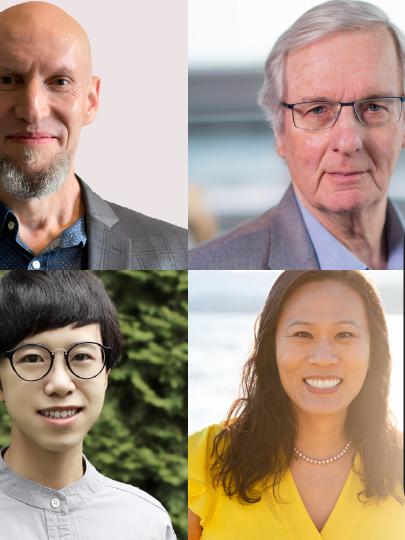

It was a project in the Engineers in Scrubs program, which is in the Biomedical Faculty at UBC, and then two group members, Marianne Black and Lawrence Buchan stayed on, and that was when they added me, Elise [Huisman] and Jeremy [Kooyman] to the team.

I think I already feel successful. We’ve got now 18 drill covers in Uganda, the drill covers are being used, they’re very helpful in being able to conduct more surgeries in a given week, and happy to grow it as big as it can be where it’s still being used and being useful. If that means every orthopaedic surgeon in every developing country in the world, then that’s amazing. And if that means that it’s only going to be useful in a few select countries, then that’s amazing too.

I see our team as a shepherd of this idea. I think it’s a good idea that needs to be well-designed and implemented, because it has a lot of power to help a lot of people.

Learn more at www.drillcover.com